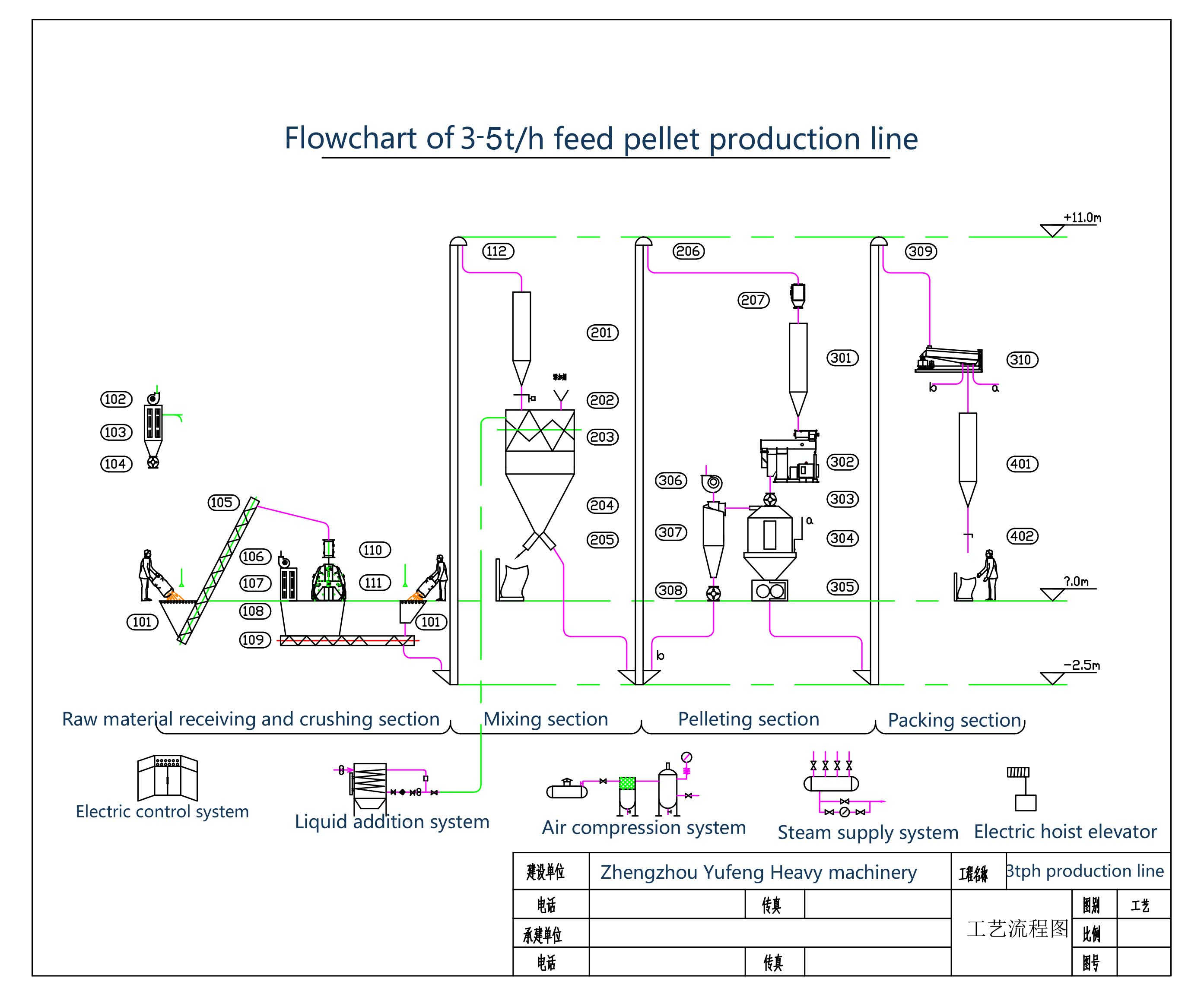

3-5 t/h Feed Pellet Line for Poultry & Livestock

This Feed Pellet Line can be used to make feed pellets for all ages chicken and other animals. And it is a good choice for the farm owner and those who plans to step into the poultry feed making industry. The feed pellet can be used to your farm, or also can be used for marketing.

Production line installation site Production line installation site

Production line parameters:

Grain hammer mill: SFSP56*40 (37 kw)

Mixer: SLHY1 (7.5 kw)

Pellet Mill: SZLH 320 (37 kw)

Conditioner: TZQ30*200 stainless steel. (2.2 kw)

Total Power: 138.95 Kw.

Production line Floor space:

9*5*12m ( L * W * H)

Advantage:

1. when the thickness of the raw material is >5 mm, a hammer mill is needed to reduce the size to ≦3mm.

2. mixing section is suitable for mixing premix, poultry feed, aquatic feed, additives, etc.

3. as the key of the whole feed processing line, pellet machine adopts evenly mechanical feeding, high speed rotating centrifugal distribution into the granulating chamber, through the scraper to distribution materials, with strong internal structure and smooth surface for the finished product.

4. After pelletizing, the temperature of the feed pellet is about 60-80 degrees Celsius, with a moisture around 15%. A Cooler be used to reduce

the moisture to 3-4% roughly for easy store.

5. Classifying screen is applicable for screening and classifying of mash or pellet feed. It is also can be used for the cleaning of raw materials and the classifying of semi product.

6. In order to protect the feed pellet from moisture and other environmental conditions, after cooling and screening, there is the packing process, which is effectively handled by the packing machine.

Raw materials, etc.

1. The raw material could be all kinds of grains, such as corn, maize, wheat, barley, etc.

2. According to different formula, there are also other kinds of materials, like premix, vitamins, wheat bran, salt and others.

Send your message to us:

-

3-5 t/h Feed Pellet Line for Poultry & Livestock

-

3-5 t/h Feed Pellet Line for Poultry & Livestock

-

3-5 t/h Feed Pellet Line for Poultry & Livestock

-

3-5 t/h Feed Pellet Line for Poultry & Livestock

-

3-5 t/h Feed Pellet Line for Poultry & Livestock

-

3-5 t/h Feed Pellet Line for Poultry & Livestock

-

3-5 t/h Feed Pellet Line for Poultry & Livestock

-

3-5 t/h Feed Pellet Line for Poultry & Livestock

-

3-5 t/h Feed Pellet Line for Poultry & Livestock

-

3-5 t/h Feed Pellet Line for Poultry & Livestock